How Can Cork-Based Vibration Damping Solutions Extend the Lifespan of Electrical Equipment?

In the power industry, where transformers, reactors, and substations operate continuously under harsh environmental and electrical conditions, ensuring long-term reliability is critical. One of the key yet often underestimated contributors to equipment degradation is vibration. By implementing effective vibration control strategies, companies are not only enhancing performance but significantly extending the operational life of their assets.

Power transformers and associated equipment inherently produce mechanical vibrations, mainly due to magnetostriction in the core materials, the operation of cooling system elements such as fans and oil pumps, and resonance between mechanical structures and electromagnetic forces.

These vibrations can lead to material fatigue and micro-cracking, structural damage to tanks and enclosures, loosening of mechanical joints, and accelerated aging of seals and insulation systems. Without adequate mitigation, the result is increased maintenance costs, unplanned downtime, and reduced equipment lifespan.

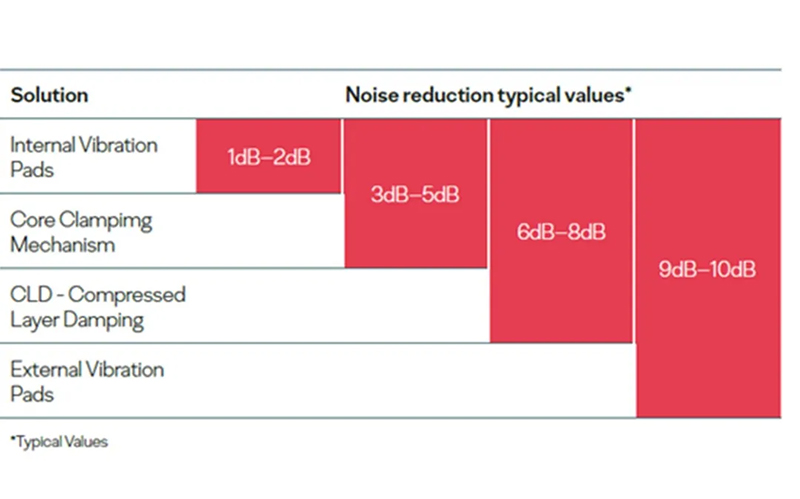

These solutions have demonstrated the ability to reduce noise by up to 10 decibels and isolate more than 95 percent of vibrations in real-world transformer installations.

The use of cork-based damping materials directly supports the long-term operation of transformers and reactors. With high recovery and creep resistance, cork composites maintain mechanical stability under sustained loads. For example, Amorim’s VC2100 and VC6400 pads, used in transformers weighing up to 48 tons, have achieved isolation rates of up to 98 percent during field applications.